As everybody knows, Aviation is kind of a conservative world: MRO doesn’t make an exception to this rule – #MRO #AR #Drones

Reasons of the above are well founded: failure is a forbidden word in commercial aviation and when it comes to the approval of new design, Civil Aviation Authorities require severe testing, fail safe approach and reliability analysis.

Usually, the certification process takes that long that aircraft manufacturers prefer to rely on an “evolutionary” rather than “revolutionary” approach.

As a result, even at the core of the most advanced avionic systems, we find micro-processors that are “ages” behind the current cutting-edge technology.

If the conservative approach is valuable and, somehow, mandatory for certain areas of the aviation industry, there are cases where a more creative and dynamic strategy is needed, in order to better serve the final customer by leveraging on ready-to-use technology advancements.

What is new for MROs

Well, the correct heading might rather be: “what is already available for maintenance organizations while they are still pretending it doesn’t exist”!

You know, when you have new technologies that can increase the quality of the work, can reduce aircraft ground time and, icing of the cake, can radically cut costs, you might be better seriously considering them and ironing out whatever resistance – internal or external – you may find across your continuous improvement path.

Many advancements are nowadays ready to be deployed or, for a few far-sighted MROs, already being used although not fully integrated in day-by-day operations: IoT applied to aircraft, spares, tools; electric ground support equipment; electronic logbook; Blockchain for digital certification and many other new technologies.

In this post we are going to focus on what we believe are the most powerful efficiency driver in the above scenario: Augmented Reality and Drone Inspections.

Augmented Reality in aviation

With the AR word we identify a technology that by using a portable – better if wearable – device , can enhance the inspector vision with meaningful information like, drawing, written and aural instructions, warnings and so on.

Usually, we find three main use cases for AR:

- Remote expert assistance

- Guided inspection check list

- Training

The trick on all the above cases lies in the concept of collaboration and experience sharing: with the help of smart glasses, the remote expert can see what the operator on the field sees and can provide additional information and instructions.

The ability to record sessions and to design in advance the workflow yields a tremendous boost to the training and to the dissemination of best practices.

Industry experience shows that AR can improve productivity up to 40% compared to the traditional physical Job card.

DRONE Inspections

Should someone drive a poll to list the most painful tasks in the aviation MRO, certainly at the top ten we would find Lighting strike inspections. Anybody with some field experience will certainly remember the painful waiting time lost in finding the right cherry picker and that feeling of pain in the gut that comes from being at 30 feet high on an unstable and shaking platform…

Now, the above task, and many others that include routine inspections during planned maintenance, can be easily and quickly carried out by using a Drone.

The current technology in drones has seen significant improvements: advanced radar/lidar automatic guidance and high-resolution cameras can perform – and record – the aircraft surface in a much better way than human eye.

Here the brightest gain for the MRO – and for its final customer – comes from the reduced ground time and lower investment.

Certification considerations

From the above celebratory discussion, one might wonder why both AR and drones aren’t adopted by the majority of MROs around the world: the business and quality cases are certainly more than compelling.

An adverse combination of external and internal resistances can explain the situation.

First, Aviation Authorities, as conservative as they can be, are not apparently enthused to amend their regulations in order to admit new tools and procedures that may drastically change the old and reassuring habits of conducting maintenance inspections.

Despite a strong support from the industry, as of today, the only go-ahead from FAA and EASA (US and European aviation authorities) is limited to some instance of remote inspection in the production and design regulations (so-called part 21).

Coming to internal resistance, the adoption of these new technologies requires strong management commitment to change; ability to effectively communicate the goods of the new technology and willingness to wipe off the concerns about workers privacy (this especially when we talk about AR…).

The way to go.

The MRO industry after Covid-19 will face many challenges: we still don’t know when and how the rebound in traffic will happen.

One thing, though, we know for sure: the pandemic crisis made it clear to every stakeholder in very industry in the earth that revolutionary steps in technological transformation need to be taken.

The ability of AR and Drones to deliver consistent and tangible advantages to the airlines – in term of aircraft downtime and quality of maintenance – is going to be a must-have for the next decade successful MROs.

The advise to the wise MRO is to start implementing AR and drones in every day operations, recording each inspection and repair while still keeping the existing – approved – procedures: the approval of the new technologies from the Aviation Authorities will be easier and quicker once the organization will prove the higher effectiveness of the new tools.

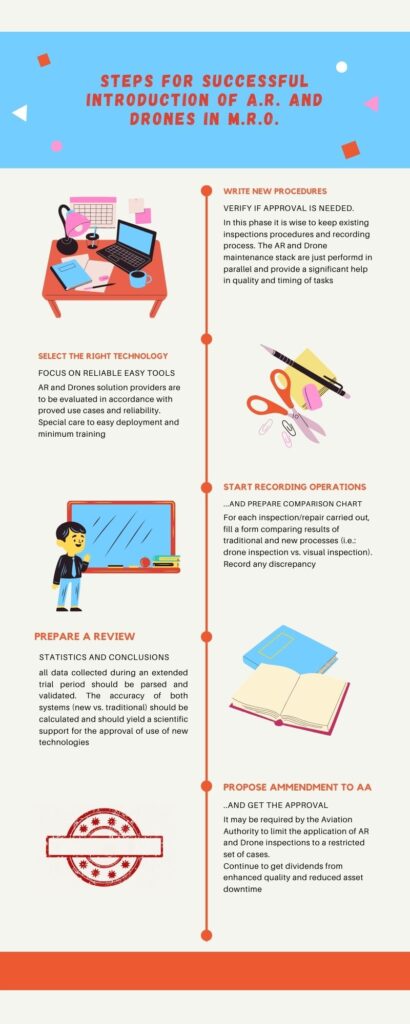

A quick overview of suggested steps for AR and Drone inspection implementation is provided in the picture below.