How Reliability Analysis can help

Aircraft components – Cost for repair

There is a consensus in literature about airline maintenance costs representing between 10% and 15% of total expenditure: that’ a big number.

What about maintenance cost of aircraft components?

Here the number is variable, depending on the type of aircraft, age, logistic and so on.

Based on our direct experience and taking for example the Airbus A320 we can provide a rough – just for discussion - number: 80 USD per flight hour.

To put the above number into context, let’s take a small airline with 5 A320 - each of them flying 2000 flight hours per year: total maintenance costs for components would be around 800.000 $ per year….not a small mountain!

Reliability analysis can trim down the above costs in a range of 5% to 15%...if the airline in subject can consistently save 80k per year...that's quite a significant contribution to the bottom line.

Let’s see in details how reliability analysis can help.

First: what exactly is reliability analysis?

As per IEEE (Institute of Electrical and Electronics Engineers) definition, Reliability describes the ability of a system or component to function under stated conditions for a specified period of time.

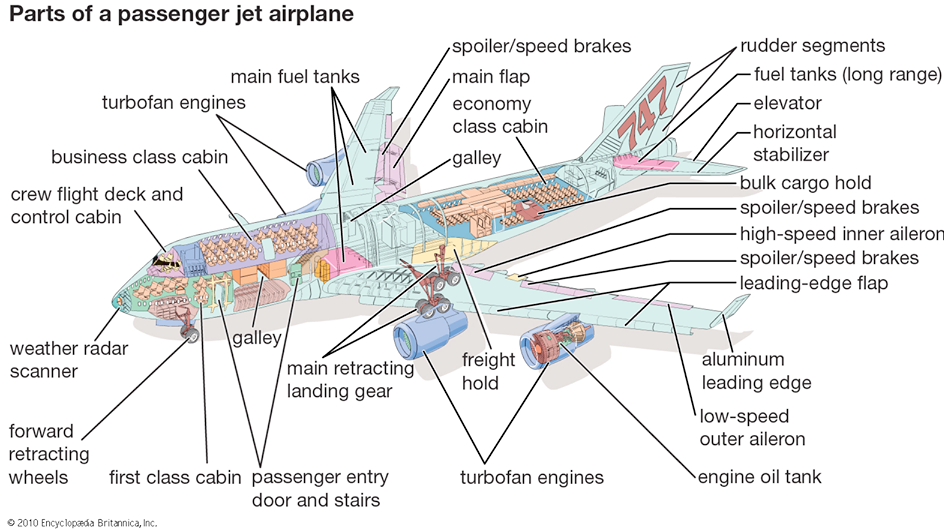

If we consider a complex system like the aircraft, Reliability is a term that basically defines the ability of a certain component (a.k.a. Line replaceable Unit) to operate without malfunctions for a measured period of time.

In the aviation world, Reliability analysis is not an option: Aircraft Maintenance programs are all based upon reliability analysis and are subject to periodic reviews and amendments as the data from the operational field enrich the knowledge about failure root causes.

Reliability of a component is basically measured in Mean Time Between Removal – expressed in Flight Hours – or (to distinguish failures from other causes of removal) Mean Time Between Failure.

The recipe: two ingredients are needed for a good Reliability Analysis

The list of components (LRU) for a modern commercial aircraft is in the triple-digit number: the picture below is just a pale representation of the population and location of aircraft parts.

Because of the complexity – in numbers and in variety of aircraft components - we need to have a good Maintenance Information system in place, able to track at least these basic data:

- Aircraft flight hours count

- Installation/removal time of each component

- Reason for removals

- Repair shops findings

Is a good Maintenance Information System just enough? No!

We also need a well-designed organization to feed the Maintenance System with the right food: if you don’t insert timely and correct data – like aircraft flight hours or removal reasons – you won’t be able to track meaningful conclusions.

OK…now that I have good reliability data…what advantages can I get?

Well, three families of cost savings are at your disposal:

- Optimum Spare parts stock level

- Repair costs

- Less flight delays and cancellations

Let’s see each one of them.

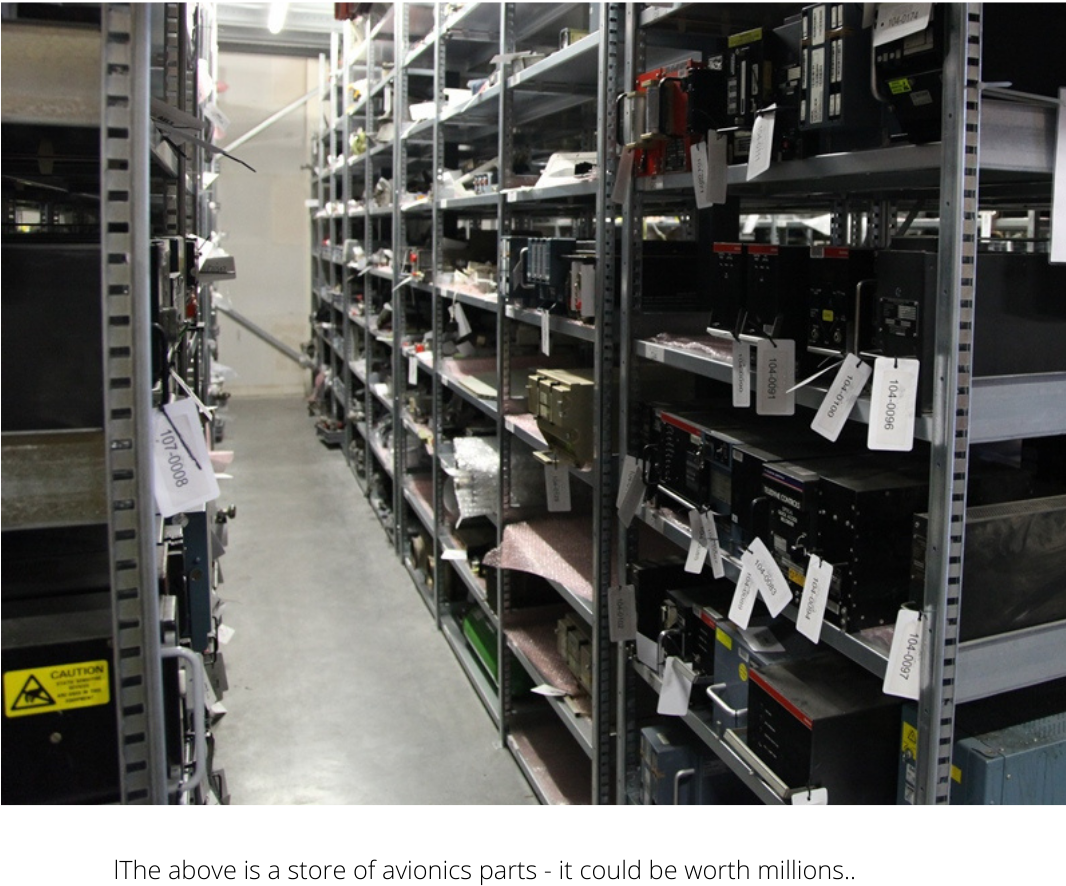

Optimum spare parts stock size

Airlines need to size their stock with the best compromise between minimum investment and maximum operational support: certainly, nobody wants to have a 50 million worth of an aircraft stuck in the airfield waiting for a brake pack or a hydraulic actuator.

On the other side, an oversized stock will cost dearly in terms of working capital and risk of obsolescence.

Therefore, optimization algorithms are at your disposal to calculate the exact quantity of spares needed for each mandatory LRU installed on your fleet.

Two variables are of paramount importance for the optimization algorithm to work: Turn Around Times (the time needed for a faulty unit to be repaired and back in the stock) and – guess what? – Mean Time Between Removal.

So, MTBR data must be correct to yield an optimized output in terms of stock size.

Another important effect of a well-managed reliability analysis is that an improvement of MTBR yields a reduced stock size, thus providing a first cost cutting beneficial result.

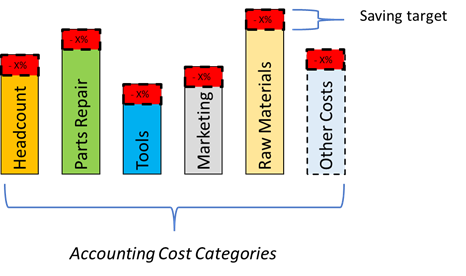

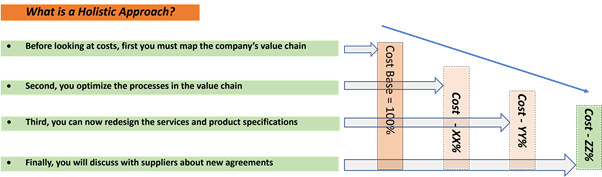

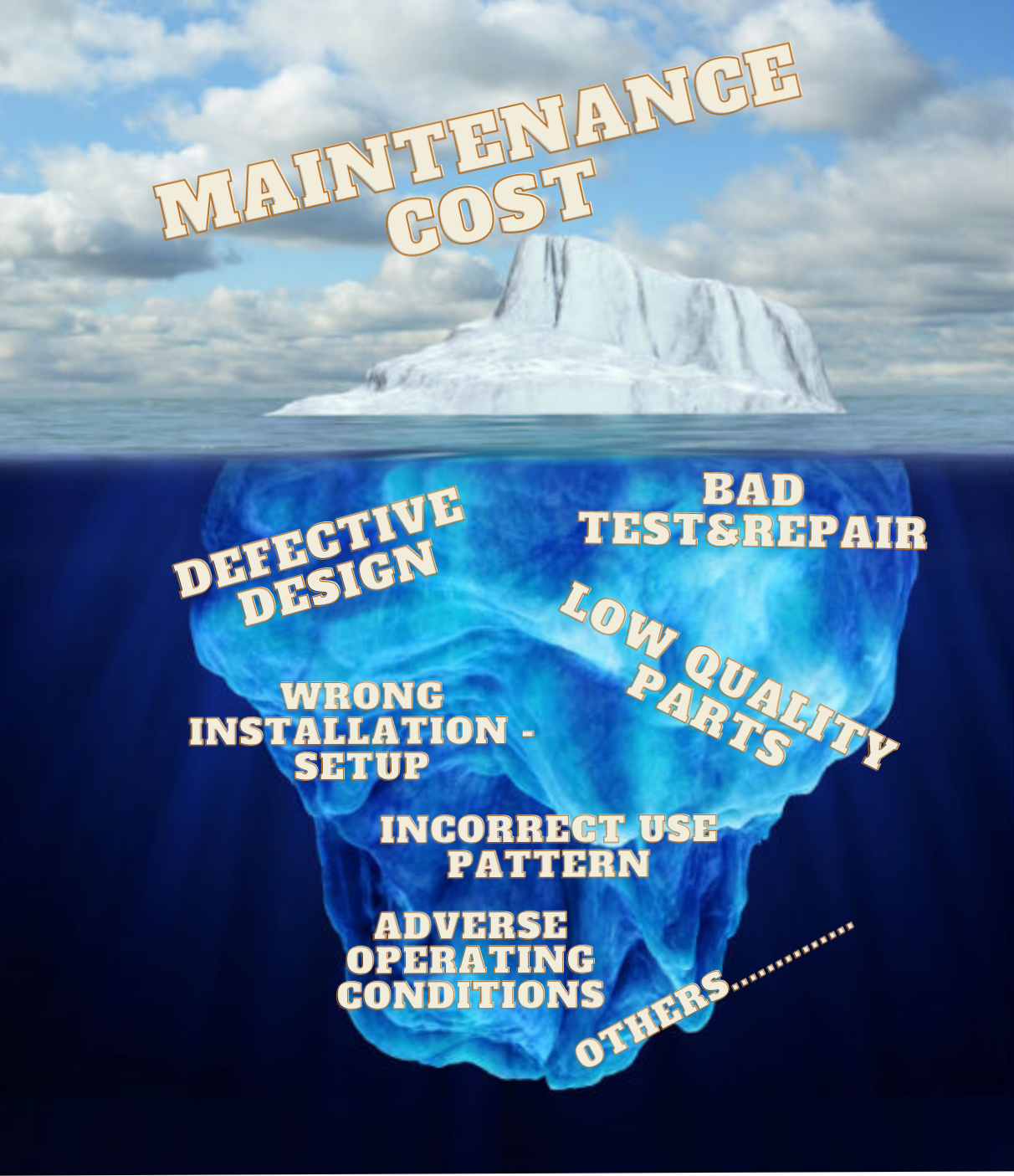

Repair costs

Line replaceable units can fail for various reasons: defective design, uncomplete repair and testing procedures, low-standard replacement parts, wrong installation procedures, incorrect aircraft handling, adverse operation environment.

A well-managed Maintenance Information System keeps track of at least two important data: Reasons of (LRU) removal and Shop Findings.

The reliability analysis here is conducted in two steps:

1) Identification of LRUs with lower-than-expected MTBR

2) Classification and analysis of reasons of removal and shop findings

The outcome of the above reliability analysis can be various

- Design modifications or improved modification standard

- Revised testing and repair procedures (with the relevant supplier)

- Revised standard of parts procurements

- Training to line maintenance engineers

- Improved aircraft operating procedures

- Schedule preventive removal of parts

All in all, the above actions will deliver an increase in MTBR or – in other words – sizeable savings in cost of repair.

Less flight delays and cancellations

This is an obvious – but extremely sought - consequence of the good job I’ve done before.

In fact, flight delays and cancellations are closely correlated with aircraft components’ reliability.

Interesting enough, the quantification of savings here is not difficult – i.e.: less passengers reprotection costs, less aircraft on ground spare parts leasing…- but it fails to correctly represent the much higher benefits the airline will get in terms of customer satisfaction and – ultimately – loyalty.

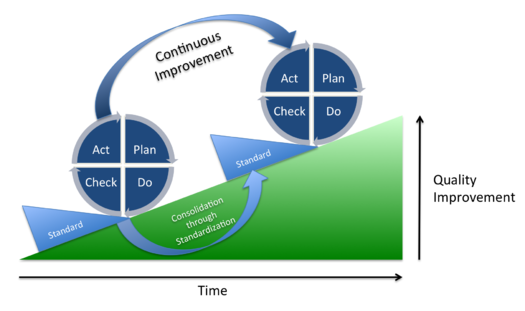

Reliability Analysis as continuous improvement cycle

Now that we have all data straighten up and our Reliability Analysis in place we suddenly realize that we have just started our trip!

In fact, Reliability Analysis involves a continuous updating of all actions we outlined in the previous section.

Is everybody familiar with PDCA cycle?

The following picture (https://creativecommons.org/licenses/by-sa/3.0 ) is very effective and self explaining...

Conclusions

Reliability analysis is a powerful tool to reduce costs and increase operational efficiency, but to exploit its potential benefits the airline or MRO must invest on an effective Maintenance Information System and deploy an efficient data collection process: data quality is paramount.

The other important concept about reliability analysis is that it is a continuous improvement path: we'll never stop finding new measures to reduce rate of failure of components and systems.